Definition

Any tangible elements included in a product are considered direct materials in cost accounting. Ingredients for a cake, auto parts, and fabric for apparel are a few straightforward examples of direct materials in production.

In manufacturing enterprises, direct material spending accounts for up to 80% of overall spending. Over 80% of your pricing strategy, competitive advantage, quality, customer satisfaction, and innovation potential would be represented by this. Direct materials are simple to detect, quantify, and link to manufacturing costs directly.

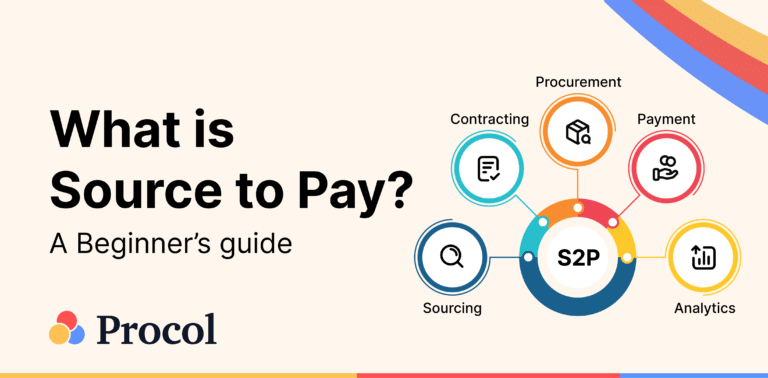

Direct Material Sourcing

Direct procurement relies on supply stability, but market instability and price swings present unique difficulties. Long lead periods, international suppliers, and a significant reliance on forecasting and logistics performance may all be involved.

Direct material sourcing requires knowledge, experience, thought, and care. The purchase of direct materials necessitates substantial coordination, as there are several internal and external partners and countless operations to plan, track, organiae, and manage.

Your product’s quality is determined by the direct materials you use, which impacts your competitive edge and customer happiness. Consequently, quality management is crucial to direct purchases. Different material types and categories have other quality management procedures.